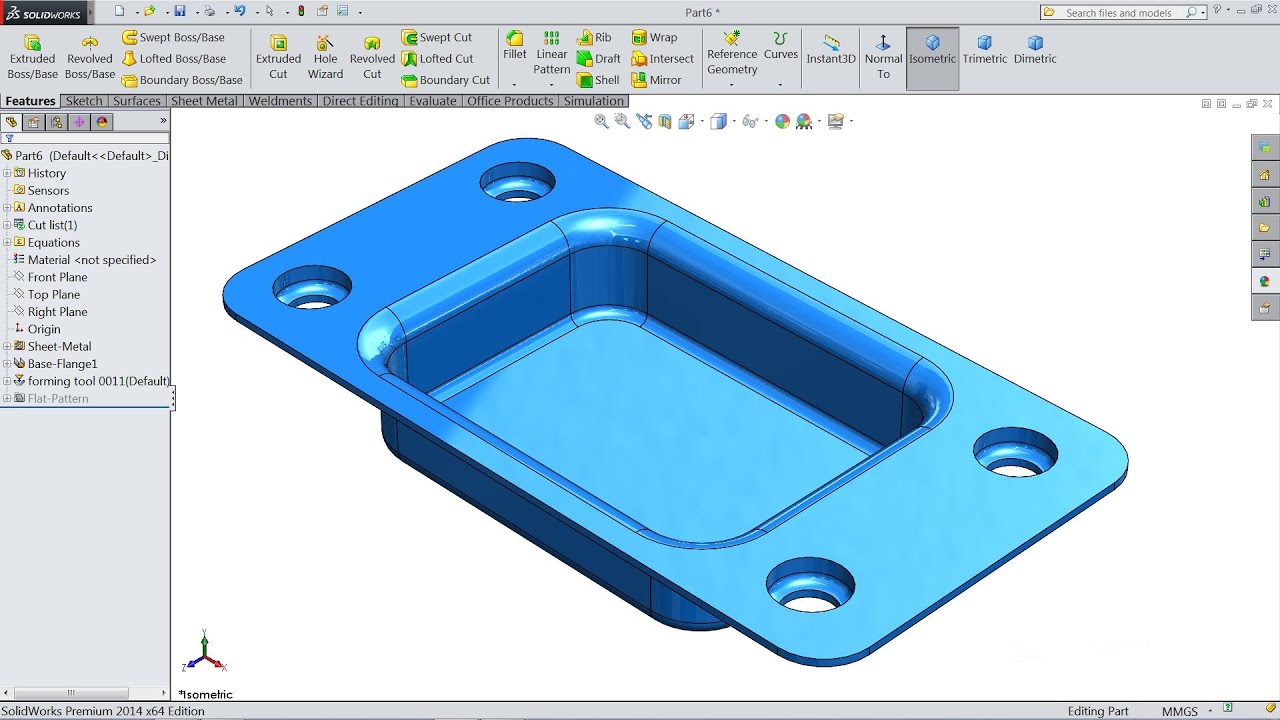

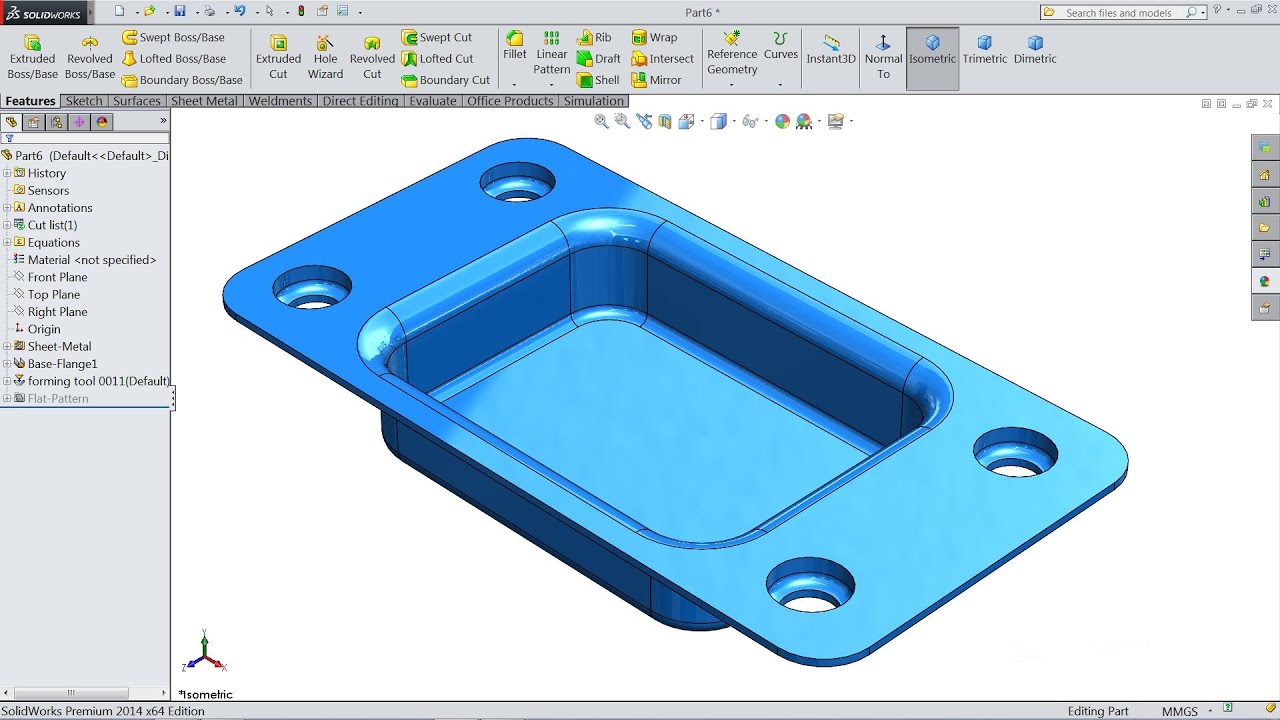

Hi all there are a number of methods use to stiffen a flat sheemetal panel such as ribbing crossbraking etc.

How to stiffen sheet metal panels.

I need some thing thin.

It works perfectly for creating stiffening ribs in sheet metal parts as you ve described.

Use the pro e form tool within the sheet metal module.

The most common way to add grooved seams to sheet metal is to use a bead roller.

It may not unbend or it may simply ignore that feature.

If you want more damping try already impressed patterned plate with different patterns such as treadplate.

If it s the latter that s o k since in reality you don t add any.

Use a brake to bend the four edges up and use a single pass mig weld down each corner.

The simplest and cheapest option is to cnc bend the sheet metal component with a stiffening form.

This form is simple part of the bend that is not complete and is achieved by having a gap in the cnc bending blade and a point below deforming the sheet metal during the standard bending process.

How do you stiffen sheet metal panels.

Im wondering how to stiffen it up.

Or more from the edge on everything else.

I was thinking maybe using so thin aluminum sheets i have laying around.

I don t recall how it handles the feature when you do an unbend all.

My 92 sundance has a card board door panel with cloth wrapped on it.

Panel fasteners and other types of pem hardware can be added to bolster sheet metal parts or provide threads for assembly.

This is also like flanging but then instead of an l its more.

With a bead roller you put the metal between a male and female die that are tightened down to press the design that is cut into the dies into the metal.

Anyway in addition to what everyone else has suggested basic good design for stiffening sheet metal is to stagger your stiffeners so instead of putting all the bumps in a row which simply makes the gap down the center the weakest point you d want 3 smaller bumps in the intermediate rows so it would be 2 3 2 3 2.

Thick or less and 1 8 in.

Curious to know what you use to increase the stiffeness of the panel w o adding a significant amount of.

This piece will look like an unfolded box lid when laid flat.

Holes and slots these should be placed at least 1 16 of an inch from the nearest wall or part edge for materials 0 036 in.

The most simplest way is to bend the boundary of the sheet slightly in an l shape wherever possible.

I would cut a sheet metal blank from a single gauge material one piece.