The linear weld corner relief terminates on a point the arc weld corner relief shape terminates with a straight line segment.

How to weld a sheet metal corner shut in inventro.

The default settings are specified in the sheet metal styles dialog box.

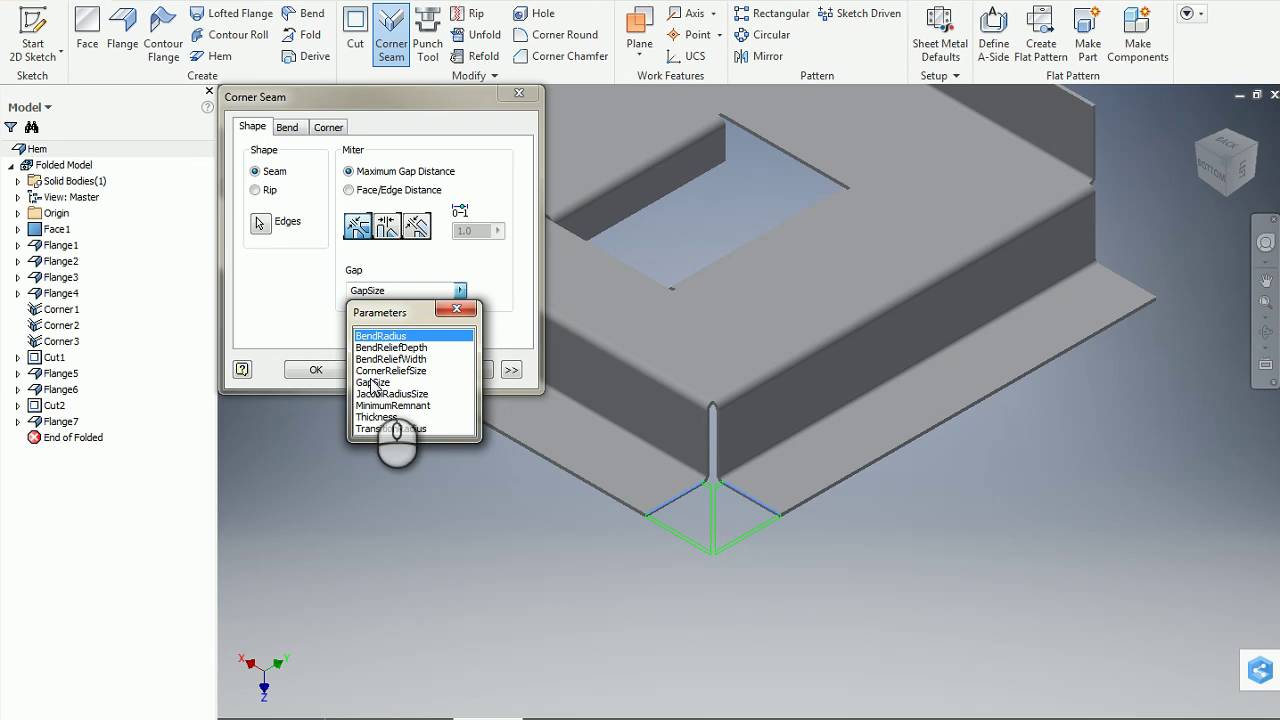

In the corner seam dialog box you can.

In this tutorial video we will learn sketch sh.

Click the corner edit glyph for your selected corner.

Not all options described are available or valid for.

Tig welding sheet metal.

Click the corner tab on the contour flange flange or corner seam dialog box.

Inventor sheet metal corner relief options duration.

Don t attempt to weld thin materials like sheet metal with flux cored wires which put more heat into the base metal.

To specify a corner relief.

In part 22 of the autodesk inventor 101.

Inventor elbow modeling welding duration.

Change these parameters for individual features using the corner options tab.

To specify an overlap gap select overlap gap.

You can also use the real value edit drop down list on this field to specify a percentage of overlap with either the overlap or reverse overlap type enter a value from 0 to 1 for overlap gap.

To specify an overlap that differs from the value specified select overlap type in the corner edit dialog box.

Overrides default parameters that define how corners are relieved when a folded model is unfolded.

For more information about corner reliefs see to work with corners in sheet metal feature.

The new laser weld corner relief terminates with a tangent arc and is more suitable for laser cut parts.

Accept the default seam type or select another of the three seam types.

Forget the larger 1 8 inch tungsten electrode and use a smaller one.

The basics series we ll take a look at how to use the basic functionality of the sheet metal environment in autodes.

On the ribbon click sheet metal tab modify panel corner seam.

To weld sheet metal with solid wires use electrode positive ep or reverse polarity.

Laser weld relief shape.